Precision technologies

PRODUCTION FLEXIBILITY

Sliding headstock turning

The company has 40 sliding headstock lathes. Bar passage: Ø 2 mm – Ø 38 mm. LFV technology: Low Frequency Vibration cutting

Turning on a twin-spindle lathe

The company has 9 lathes with 2 and 3 turrets. Maximum bar passage: Ø 80 mm. Workable diameter: Ø 6 mm – Ø 400 mm

Multi-Tasking

Maximum workable diameter: Ø 400 mm. Maximum bar passage: Ø 75 mm

Robotic turning centers

The company has three lathes powered by loading robots.

Turret turning

The company has 11 turret turning centers equipped with bar feeders for automatic or operator-controlled machining, for the production of flanges and shafts.

Special Metal Turning

The company has two turning machines for high-precision hard turning. Tolerances of +/- 2 µm can be achieved.

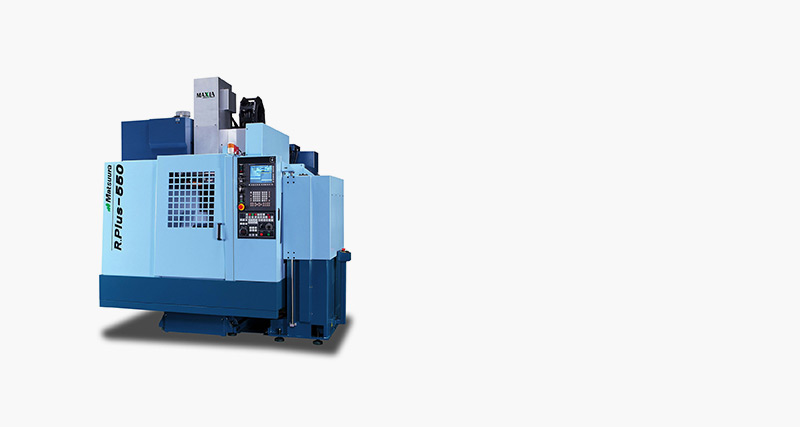

Milling

The company has 3 machining centers with pallet changers. Working area: 500 x 400 x 400.

Centerless grinding and rolling

The company has a centerless grinding machine and 3 rolling machines.

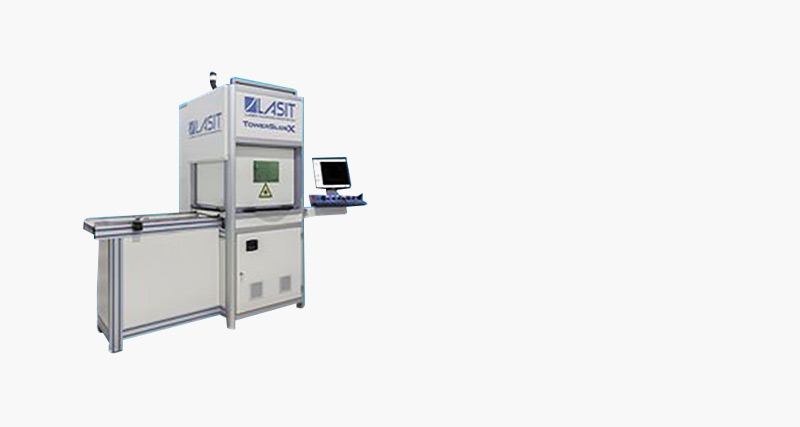

Laser marking

The company has a laser marking machine capable of engraving serial codes such as bar codes, IQR codes, and various vectors on all ferrous and non-ferrous metals.

Unitary control and detection stations

The company manufactures control systems for specific characteristics and monitors processes with real-time data acquisition stations.

Laser dimensional control

The company has an automated laser measuring device for measuring trees. Diameters and lengths can be measured with a resolution of 0.1µm.

Washing system

The company has two vacuum washing systems that use modified alcohols. This system meets the most advanced cleaning and environmental requirements.

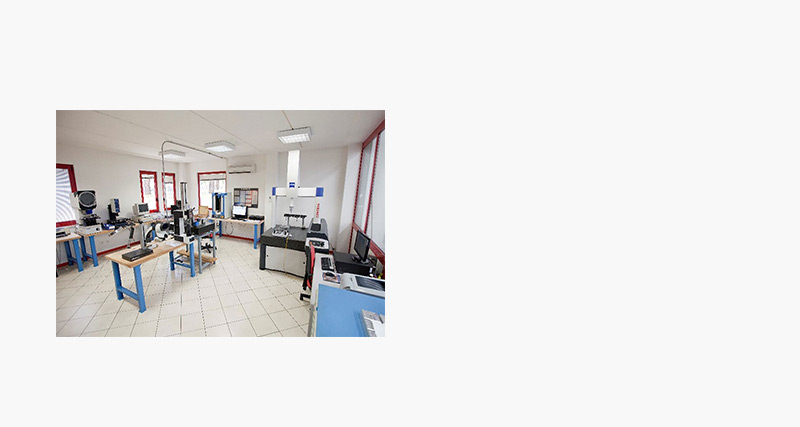

Metrology laboratory

The company has a fully equipped metrology laboratory designed to meet the quality requirements of our customers. It is equipped with specific instruments for performing thermal and humidity checks.